16573487_ed6 EN-1

EN

Product Safety Information

Intended Use:

These die grinders are designed for grinding, porting, polishing, de-burring, and breaking

sharp edges.

For additional information refer to Air Die Grinder Product Safety Information Manual

Form 04580288.

Manuals can be downloaded from www.irtools.com.

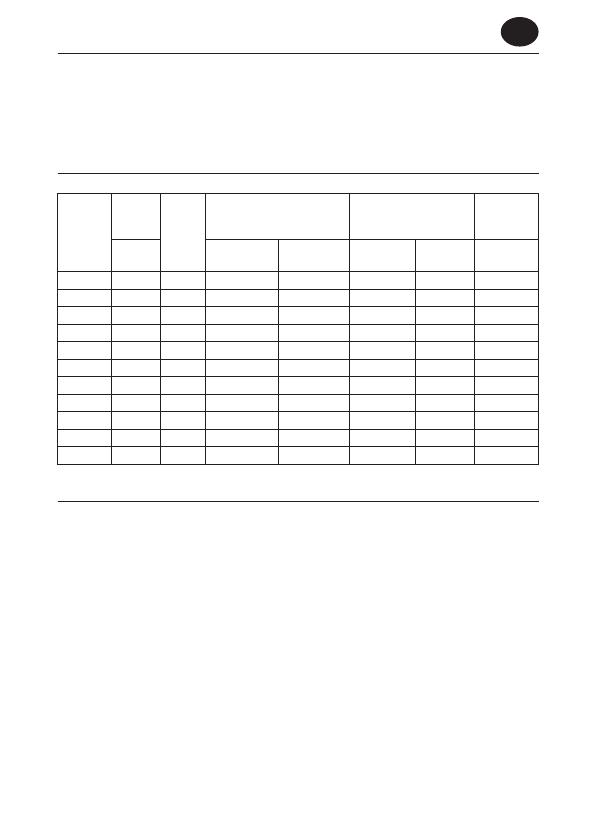

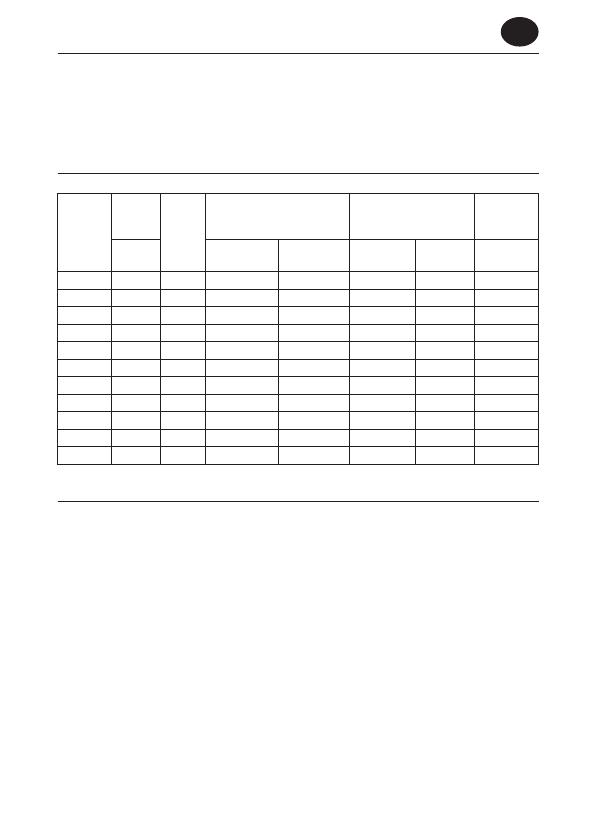

Product Specications

Model(s)

Free

Speed

Collet

Size

Sound Level dB (A)

(ISO15744)

Sound Level dB (A)

(ANSI S5.1-1971)

Vibration

Level

(ISO8662)

rpm

† Pressure

(L

p

)

‡ Power (L

w

) Pressure

Power

(ISO3744)

m/s²

301 20,000 1/4” --- --- 91.8 104.8 3.3

301-EU 20,000 6 mm --- --- 91.8 104.8 3.3

307A 27,000 1/4” 83.0 94.0 --- --- 4.9

307A-EU 27,000 6 mm 83.0 94.0 --- --- 4.9

308A 25,000 1/4” 91.0 102.0 --- --- 4.0

308A-EU 25,000 6 mm 91.0 102.0 --- --- 4.0

3102 20,000 1/4” 90.0 101.0 --- --- 2.5

3102-EU 20,000 6 mm 90.0 101.0 --- --- 2.5

3107G 27,000 1/4” 92.4 103.4 --- --- 2.6

3108 25,000 1/4” 92.0 103.0 --- --- 3.4

3108-EU 25,000 6 mm 92.0 103.0 --- --- 3.4

† K

pA

= 3dB measurement uncertanity

‡ K

wA

= 3dB measurement uncertanity

Installation and Lubrication

Size air supply line to ensure tool’s maximum operating pressure (PMAX) at tool inlet. Drain

condensate from valve(s) at low point(s) of piping, air lter and compressor tank daily. Install a

properly sized Safety Air Fuse upstream of hose and use an anti-whip device across any hose

coupling without internal shut-o, to prevent hose whipping if a hose fails or coupling discon-

nects. See drawing 16573164 and table on page 2. Maintenance frequency is shown in circular

arrow and dened as h=hours, d=days, and m=months. Items identied as:

1. Air lter 6. Thread size

2. Regulator 7. Coupling

3. Lubricator 8. Safety Air Fuse

4. Emergency shut-o valve 9. Oil

5. Hose diameter 10. Grease - through tting